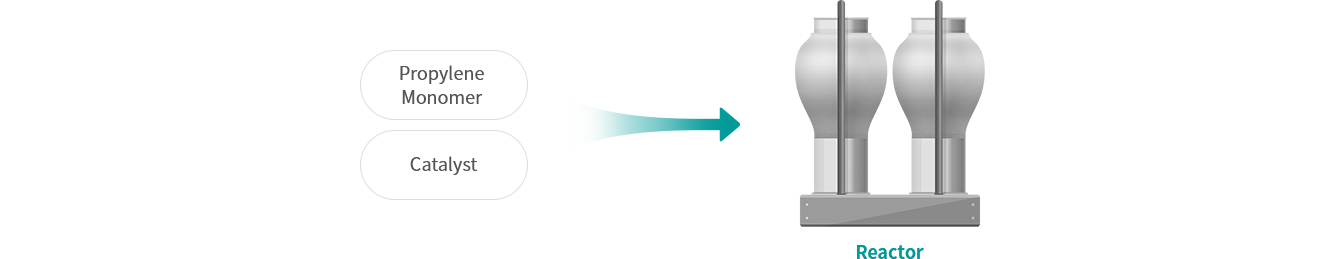

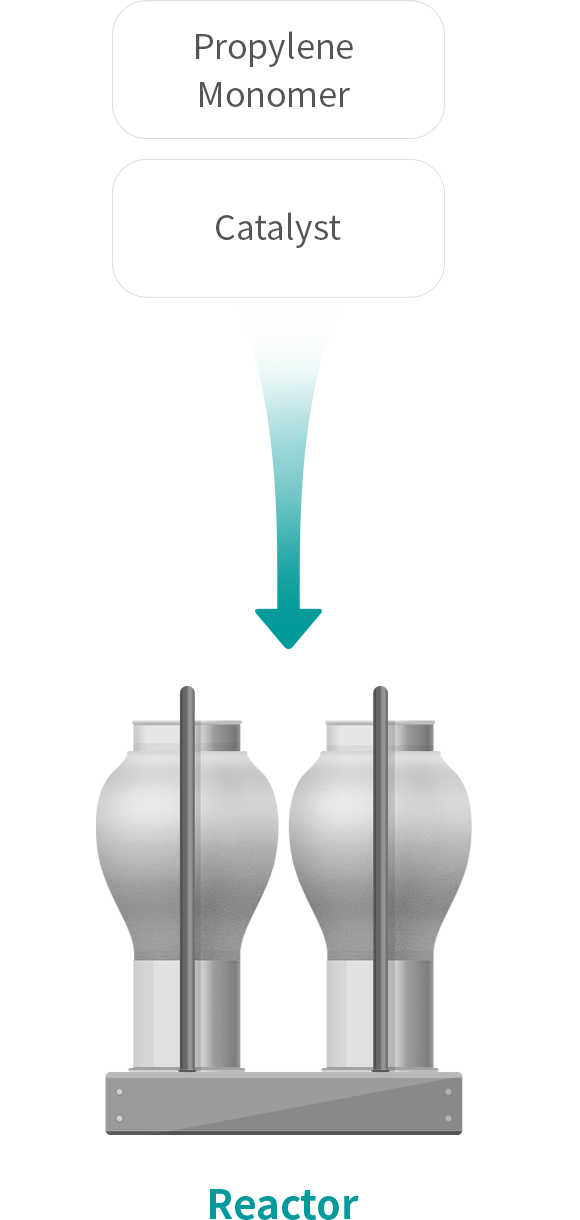

Unipol process (vapor-phase polymerization) developed by UCC

Reaction by direct contact of vapor-phase PL and the solid catalyst

Wide distribution of molecular weights of products

Regulation of molecular weight distribution through cracking

Low operation cost due to low utility consumption

Difficult to operate due to numerous property-regulating variables such as temperature, pressure, and composition

Adoption of fluidized bed reactor in PP polymerization process

Simple handling of solids and easy discharge of fluidized solids through reactor nozzle

Quick mixing as solid particles are in continuous movement

Excellent heat and mass transfer between vapor and solid with heat easily transferred through moving solid � particles (ease of temperature control)